Oct 4, 2013 | Posted by Matt Elson

Something that I have heard over and over again is the “lack of skilled workers” in Canada (and in North America, in general). I heard this at CMTS earlier this week a lot (Side Note: Great job from @SME_MFG for being a supporting partner at the show!).

The common refrain is something like this: “Canada could better compete if only we had more skilled workers” or “We would hire more people, but we need specific skilled workers to fill the gaps.”

I think it can be a lot of hot air! And I’m not alone. Julian Beltrame of the Canadian Press says that recent studies have found “no major imbalances” in matching skill levels with jobs, and CBC News reports that “there are a lot of ‘anecdotes’ about the skilled labour shortage, but not much evidence”.

It could be that Canadian companies are using this as an excuse not to hire, or not to invest in training & development of their human resources. I spoke to one business leader recently who said that people have a limitless potential to be “re-purposed” into other jobs if their current role becomes obsolete or there are higher demands in other areas. (This incidentally very closely mirrors deep TPS thinking that says people are by far the most important assets any company can ever have. An internal saying goes “Before we build cars, we build people.”)

What has been your experience with training and development programs? My experience ranges from lukewarm to downright terrible, and I have heard some horror stories from all industries around the world. Training takes time! It also takes dedicated, focused and structured effort to do right!

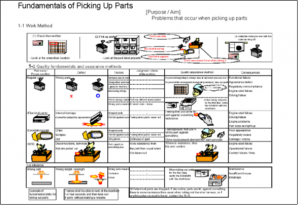

One of my most satisfying moments as a student of TPS came in a plant where the team was working on making improvements in an area. We had made great strides in implementing standardized work, one piece flow and stabilizing the machine output. The area ran like a top (98-99% OA), except on one particular shift. Being the students of TPS that we are, we practiced genchi genbutsu and went to the shop floor to investigate. After a short observation, we noticed one team member that was struggling on a work station in the cell, and that had the effect of causing problems for the whole cell (one piece flow doing its job!). The team leader stated: “That guy always slows us down, we need to talk to him.” Turns out that the team member was struggling to pick, orient and load rivets that were a part of the process…this was causing cycle time fluctuation and dropping the OA. Our immediate answer was more training was needed (remember, in TPS, it is NEVER the team members fault!)…local management was skeptical. “How much more training does he need?” Our answer: “As much as it takes.” To give them credit, management made some staffing changes and allowed us to pull the team member out of production for additional training. We made an off-line mock up of the cell in question and proceeded to train him using the incremental training method….for 3 days! That’s right, we had a team member (who was getting paid full time, but not producing one part) off line for 3 days for additional training on handling and loading of rivets. (BTW, this is NOT an easy task…think of trying to de-tangle rivets in a tote in one hand, load with the same hand, while grabbing another part with the other hand simultaneously). The result: the “problem” team member was more confident than ever and proceeded to demonstrate consistent cycle times below the takt time.

I guess the moral of the story is that if you have a skills gap…do something about it! Wasting time, money and energy on complaining (or waiting for the government to do something about it, yeah, right…) is short-sighted and a crutch for those who won’t step up to the plate.

Will it cost something to train people? Yes! Will it cost more to train more complex jobs? Yes! Will it take time to train people? Yes!

Will you lose more (money, customers, business, market share, etc.) if you don’t do something about it? YES!

So do something about it!

ME