May 6, 2021 | Posted by Matt Elson

[This was originally posted on Canadian Metalworking, here]

Many consultants, lean books and conferences/seminars tend to put a lot of emphasis on “tools”. These tools can include things like work standards, value stream mapping, 5S, kanban, andon, heijunka box, etc. Alternatively, continuous improvement is about building the capacity of employees to see opportunities for improvement every day and every hour while developing the leadership ability to sustain this culture. This is a true business excellence system – through increased employee capacity for change and improvement – developing a true learning organization.

Developing the capacity of employees and leaders is the process to create a learning organization. Getting staff to change the way they do their work is crucial in order to see long-term improvements to safety, quality, quantity and cost. Developing employee capacity has to improve the functioning of the organization as measured by these types of metrics.

While continuous improvement tools are useful for various types of problem solving, in a true improvement system, the tools are only used for developing capacity in employees. This system develops critical thinking as well as improving problem solving skills. Improvement and coaching go hand-in-hand as part of the operations management system. This is why most (depending on the source, anywhere from 80-98%) of “lean transformations” fail to achieve any actual results, short or long term; the over emphasis on tools.

True kaizen activities can typically result in extraordinary business results. This is based on my own experience, in multiple industries and countries around the world. These improvements can be in the range of 100-200% increases in productivity, 80-98% reductions in scrap or re-work, 80-90% reduction in lead-time/inventory. Additionally. there can be great advances in safety, cost and delivery. The reason that most organizations don’t achieve the results is not that this thinking process doesn’t apply, but rather the focus and effort is miss-placed. Effort on improving processes or systems alone isn’t enough. Improving our leadership is crucial, which includes the coaching and development of others. This coaching is what actually results in the process improvements, not the other way around.

Coaching is the consistent and focused process of changing behavior. It is done through practice and repetition. An improvement coach guides the learner through a series of steps specifically designed to improve experience and skill. This is just like an athletic coach or music instructor. It is the repetition of these steps, over and over again, that results in the increased capabilities. Experienced coaches seem to focus on them relentlessly. In reality, the coach is focusing on forcing the leaner into a new routine. The tools and techniques are just the easiest things to copy. As a result, this is why the emphasis on tools remains so strong.

Without the ability to evaluate our situation, coaching can not be done. Does the current condition match our target condition? Is this abnormal or normal? Is the process stable or not? Without facts, we have no way of knowing if we are actually getting better or worse. This is why an important aspect of our operations management system has to be measuring what is important to the business, and comparing this to our goals and targets. This is the framework that our coaching and improvement efforts will be based on. Only after we have a method to establish our baseline is it possible to start the improvement journey through coaching development.

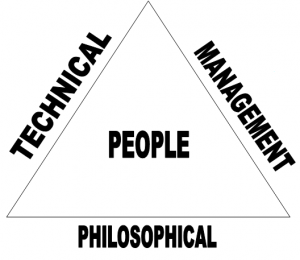

This is why we view all of these concepts as a complete, integrated system within an organizational culture. There are four parts in the systems. Each sub-system focuses on different aspects of an innovative and people based organization:

This column will feature our ongoing series on each part of this integrated system We will also be detailing the improvement and coaching method. This method will systematically accelerate the pace of learning, innovation and performance in your organization!